Price of Grade 3 Titanium Bar Medical Used Gr3 Titanium Round Bar Dental Implant Titanium Bar

Grade 3 is least used of the commercially pure titanium grades, but that does not make it any less valuable. Grade 3 is

Basic Info

| Model NO. | Grade 3 |

| Type | Titanium Bars |

| Application | Industrial, Medical |

| Technique | Cold Drawn/Hot Rolled/Forged |

| Grade | GR3 |

| Shape | Round/Square/Hexagonal/Wire |

| Diameter | 1-450 mm |

| Length | Less Than 6 Meters |

| Material Grade | Gr1,Gr2,Gr3,Gr5,Gr7,Gr9.Gr11.Gr12 |

| Standard | ASTM B348, ASTM F136, ASTM F67, AMS 4928, etc |

| Surface | Turned/Polished |

| Keyword | Titanium Bar Stock |

| Transport Package | Wooden Box |

| HS Code | 8108901090 |

| Production Capacity | 500 Tons/Month |

Product Description

Grade 3 is least used of the commercially pure titanium grades, but that does not make it any less valuable. Grade 3 is stronger thanGrades 1 and 2, similar in ductility and only slightly less formable - but it possesses higher mechanicals than its predecessors.CP Grade 3 Titanium Pipe is a commercially pure form of titanium. CP (Commercially Pure) Titanium Grade 3 Seamless Tube isunalloyed titanium providing higher mechanical strength (typical yield strength 462 MPa) compared with CP Grades 1 Tubing and Grade 2 Tubing. Cp Titanium Grade 3 Tube has moderate ductility, excellent weldability and superior corrosion resistance. CPGrade 3 Titanium Tube again promotes versatility of use and with higher mechanical strength, is used in industrial applicationswhere improved mechanical properties are required. UNS R50550 Titanium CP2 Grade 3 Tubing are suitable for a large varietyof chemical and marine as well as aerospace and medical applications where strength is a consideration. ASTM B338 TitaniumGrade 3 Welded Tubing is an unalloyed, high strength, titanium product providing excellent corrosion resistance and goodweldability. This Ti. Alloy Grade 3 ERW Tubes is primarily used in airframe and aircraft engine parts.Chemical Composition

| Grade | N | C | H | Fe | O | Al | V | Pb | Mo | Ni | Ti |

| Gr1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | / | / | / | / | / | Bal |

| Gr2 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | / | / | Bal |

| Gr3 | 0.05 | 0.08 | 0.015 | 0.3 | 0.35 | / | / | / | / | / | Bal |

| Gr4 | 0.05 | 0.08 | 0.015 | 0.5 | 0.4 | / | / | / | / | / | Bal |

| Gr5 | 0.05 | 0.08 | 0.015 | 0.4 | 0.2 | 5.5-6.75 | 3.5-4.5 | / | / | / | Bal |

| Gr7 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | 0.12-0.25 | / | / | Bal |

| Gr9 | 0.03 | 0.08 | 0.015 | 0.25 | 0.15 | 2.5-3.5 | 2.0-3.0 | / | / | / | Bal |

| Gr12 | 0.03 | 0.08 | 0.015 | 0.3 | 0.25 | / | / | / | 0.2-0.4 | 0.6-0.9 | Bal |

| Grade | Elongation(%) | Tensile Strength (Min) | Yield Strength (Min) | ||

| ksi | Mpa | ksi | Mpa | ||

| Gr1 | 24 | 35 | 240 | 20 | 138 |

| Gr2 | 20 | 50 | 345 | 40 | 275 |

| Gr3 | 18 | 65 | 450 | 55 | 380 |

| Gr4 | 15 | 80 | 550 | 70 | 483 |

| Gr5 | 10 | 130 | 895 | 120 | 828 |

| Gr7 | 20 | 50 | 345 | 40 | 275 |

| Gr9 | 15 | 90 | 620 | 70 | 438 |

| Gr12 | 18 | 70 | 438 | 50 | 345 |

★Aerospace industry★Chemical and marine applications★Electroplating industry★Medical industry★Nuclear industry★Hydro-carbon processing★Airframe skin★Desalination★Chlorate manufacturing

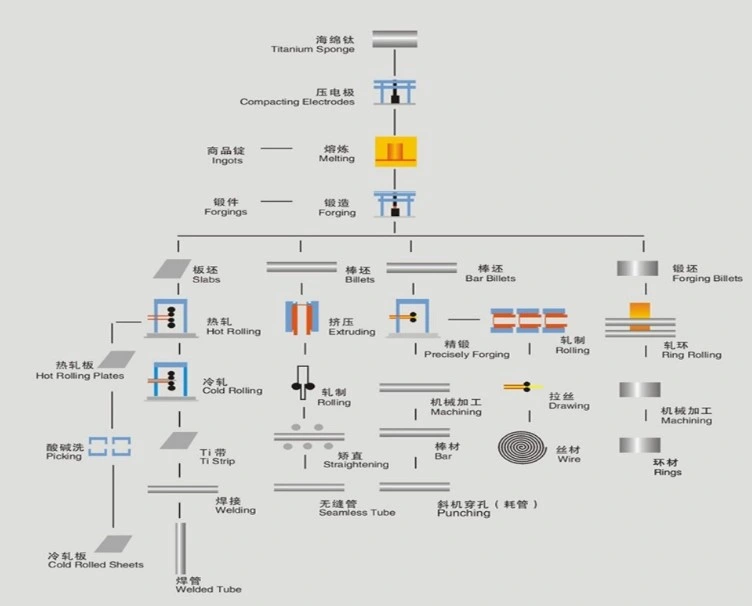

Production Process:

previous:

Titanium Alloy Bar

Send to us