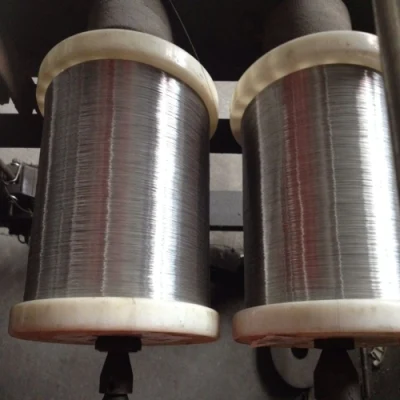

Cathode Copper Waste Copper Electrolytic Copper Electrolytic Cell, Heating Boiler, Titanium Heater, Copper Row, Copper Guide Bar

Our equipment can electrolyze 99.97-99.99% pure cathode copper from various types of waste copper such as waste wires, c

Basic Info

| Model NO. | RLKS-3000 |

| Transport Package | Export Package |

| Specification | RLKS-2000 |

| Trademark | rui lex |

| Origin | Chian |

| HS Code | 8543300090 |

| Production Capacity | 2000mt/Year |

Product Description

Our equipment can electrolyze 99.97-99.99% pure cathode copper from various types of waste copper such as waste wires, cables, car radiators, etc.We are the best supplier of copper cathode equipment in China,our electrolytic copper equipment can be customized. The production capacity: 500-30000 tons / year.

Comparing to other General companies, We have our unique superiorities of utilizing the Scrap Copper Purification Copper Electrolysis Syst. As copper is one of the unrecyclable metals existed in the world which can do great harm to the earth as well as the human beings, the copper industries have the obligation to produce the protective equipments.

Even the best chemical approach cannot remove all the impurities from the copper, it is possible to produce 99.99% pure copper with electrolytic refining. Whatever method is adopted to manufacture copper from its ore or its final purification, the process by electrolysis can be accomplished.

Since the huge profit that our equipment can bring, we sincerely welcome your honorable customers pay attention to our products. We will give you the priceable and the good-qualified equipments.

| Electrolytic copper production line An electrolytic copper equipment can improve the quality of copper as an electrical conductor and the electrolytic refining method is usually carried out in an aqueous solution. Electrolysis is the process of passing a current through an electrolytic solution or a molten electrolyte to cause a redox reaction on the cathode and anode. An electrochemical cell can undergo an electrolytic process when a DC voltage is applied. Cooper electrorefining produces copper essentially free of impurities and separates valuable impurities from copper as recover as by-products. Electrolysis and refining of copper: A blister copper (Cu 99%) prefabricated plate was used as an anode, a pure copper flake was used as a cathode, and an anion and an anode were placed in an electrolytic bath, and an aqueous solution of sulfuric acid (H2SO4 ) and copper sulfate (CuSO4 ) was used as an electrolyte mixture. Under the action of direct current, copper is dissolved from the anode (Cu) into copper ions and moved to the cathode, and the copper ions reach the copper obtained after the cathode is precipitated (also called cathode copper). This kind of copper, called "electrolytic copper", is of high quality and can be used to make electrical products. The substance deposited on the bottom of the cell, called "anode mud", is rich in gold and silver and is very expensive. It has great economic value to be taken out and processed. We are the best copper cathode equipment manufacturer in China, and our equipment can produce 99.97--99.99% copper cathode from scrap copper. Each electrolytic copper equipment production line will be customized according to the combination of the customer's raw material supply capacity and the actual production workshop scale. Tailor-made electrolytic copper production lines for customers that suit their own interests. Equipment production capacity can be customized: 1000-30000 tons/year.

| |||||||||||||||||||||||||||||||||||

Send to us